Manufacturing and Process Industries

Bluegill Energy can help reduce your operating costs and improve your quality of service and customer satisfaction with our thermal scan condition monitoring and predictive maintenance strategy services.

Equipment failures or the arbitrary three-, six- or 12-month routine maintenance model drives today’s conventional maintenance programs. Monitoring equipment performance or tracking historical maintenance data minimizes equipment downtime, extends the useful life of equipment and reduces overall equipment lifecycle costs.

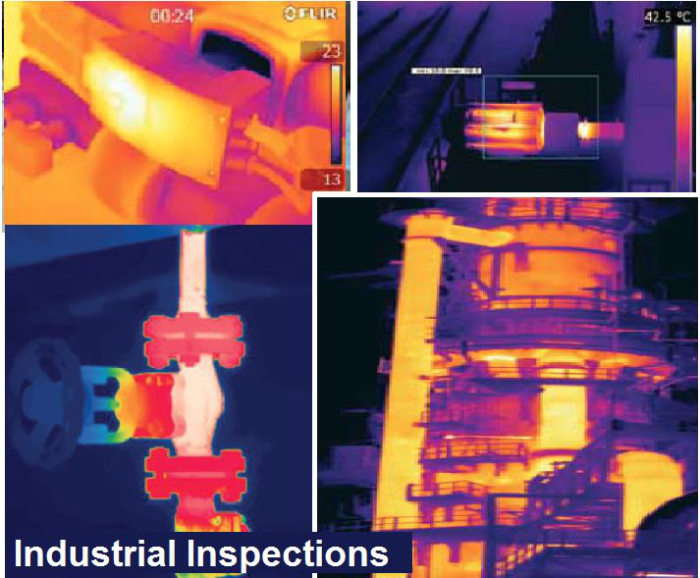

For many years, preventive maintenance engineers have used thermography to inspect motors, circuit boards, switchgear, electrical connectors, bearings and pumps, among other equipment. No longer reserved for the military and very large corporations, thermal imaging is now widely available and used by even the smallest organizations.

Bluegill Energy can help you predict the imminent failure of critical components, such as bearings and switchgear, with our thermal scan services. Our goal is to enable you to carry out the appropriate maintenance before complete breakdown, reduce equipment downtime, improve efficiency and, consequently, increase your profits.

We would be glad to answer all of your infrared thermal scan questions and provide these services in a timely manner.

Let Bluegill Energy’s trained and certified professionals make Energy Code and Green Building program compliance cost effective and easy for you!

Need more information?

Energy Code Compliance

Bluegill Energy helps companies like yours stay compliant with the…

Learn More >

Energy Code Compliance

Bluegill Energy helps companies like yours stay compliant with the…

Learn More >

Eco Friendly Design Consultation

In today’s building market, demand has grown for high-performance/low-impact eco0-friendly…

Learn More >

Eco Friendly Design Consultation

In today’s building market, demand has grown for high-performance/low-impact eco0-friendly…

Learn More >

Areas We Serve

Bluegill Energy’s certified professionals provide independent, third-party verification inspections, performance…

Learn More >

Areas We Serve

Bluegill Energy’s certified professionals provide independent, third-party verification inspections, performance…

Learn More >

- Bluegill Energy |

- P: (281) 947-3724 |

- E: info@bluegillenergy.com

- Office: 738 Highway 6 S, Suite 900, Houston, TX 77079

- Mail: 2211 Rayford Rd, Suite 111-213, Spring, TX 77386

Copyright © 2016 Bluegill Inc. | All Rights Reserved